By Kathryn Dillon

October is National Window Covering Safety Month, and as I Googled information about child safety regarding corded window treatments, I was shocked at how many kids under the age of six are injured annually. Dr. Gary Smith, the senior author of a study from the Center for Injury Research and Policy, “found that almost 17,000 children under six years of age were treated in hospital emergency departments in the U.S. for window blind-related injuries from 1990 to 2015, averaging almost two per day.” The study, which spanned 26 years, recorded 271 children dying of strangulation from corded window treatments, which is about one child each month.

To address this concern, a new safety regulation for corded window coverings went into effect on December 15, 2018. This last revision was the result of a two-year effort by the Window Covering Manufacturers Association (WCMA), Consumer Product Safety Commission, the window coverings industry and consumer groups to update the safety standards of the American National Standards Institute (ANSI), known as ANSI/WCMA A100.1-2018. At times, terminology can be confusing because the regulations are often referred to as voluntary safety standards. Voluntary simply means that interested groups of people “volunteered” to collaborate to determine safety regulations for window coverings.

The new standard separates stock products from custom products. Stock products make up roughly 80 percent of the market and are defined as those that are premade and sold in stores or online. They are sold “as is” or modified by the seller, manufacturer or distributor. The operating systems used in stock products must be cordless or have inaccessible or short cords. There is a new “Best for Kids” label that helps consumers identify cordless products.

By cordless, the standard is addressing the operating system, with lift cords being permissible. A type of inaccessible cord would be the Fashion Wand by Safe-T-Shade. This wand has the operating cord inserted into a clear wand to keep the cords out of reach.

Short lift cords are defined as being no longer than 40 percent of the length of the shade when it is in the closed position. Lift cord standards in stock products are the same as custom products with the short cord exception. These are addressed in the “standards for roman shades” section below. Any products manufactured after December 15, 2018, must comply with these new standards.

Another possibility for cordless shades is motorized window coverings. They are still the most expensive option, but they are becoming more affordable.

Custom products are defined as those that are “not stock.” This segment makes up 20 percent of the market. For window treatment fabricators, this includes the type of hardware systems we specify and use to install traversing drapes. Corded traverse rods are not compliant any longer but must be hand-drawn, use a wand or utilize motorization. However, there is an allowance with custom products for the operating cords to be longer than 40 percent of the shade in the closed position to accommodate the needs of those who are disabled, shorter in stature or elderly, and need a longer cord in order to operate the shade.

The Nitty-Gritty Standards for Roman Shades and Blinds

A child under age six generally has a head that is 17 inches or larger. Therefore, the horizontal ring spacing cannot be more than eight inches. This ensures that the space between the cord and the fabric on the back of the shade is no larger than 16.9 inches, making it next to impossible for a child to get their head in that space.

Rings must be at least two inches from the edge of the shade. When using a continuous loop cord, it must be attached to the wall with a tension device that prevents the cord from dangling. Free-hanging cords must be 40 percent of the length of the shade when it is fully covering the window for privacy. Designers must use ladder tape, shroud cord, or rings and cord locks when fabricating shades using lift cords. When custom blinds are ordered, the default to open and close the louvers is a tilt wand instead of tilt cords.

Manufacturing or custom workroom labels are more stringent with the revised standards and must include the following:

- Name of company

- City and state where product was manufactured

- Date product was made

- Stock or custom product must be designated by a “S” or “C”

- Name of client, designer or PO number so product can be tracked if needed by manufacturer

These labels can be attached to the back of the headrail, on the roller tube or on the dust board. Proper warning tags must be attached to the shades that show a graphic of a child being strangled by cords.

If the fabricator is not going to be present during the installation, written instructions must be attached to the shade. Most vendors include installation instructions with their products.

Comparing Roman Shade Operating Systems

There are many different operating systems on the market that can be divided into three different categories. They are clutch, spring-loaded and motorized. It is important to state that there is a difference between the operation system and how the cords are attached on the back of the shade and the headrail. As of press time, there is only one truly cordless shade system on the market and that is the Safe-T-Shade with wide band lifts.

Clutch Systems

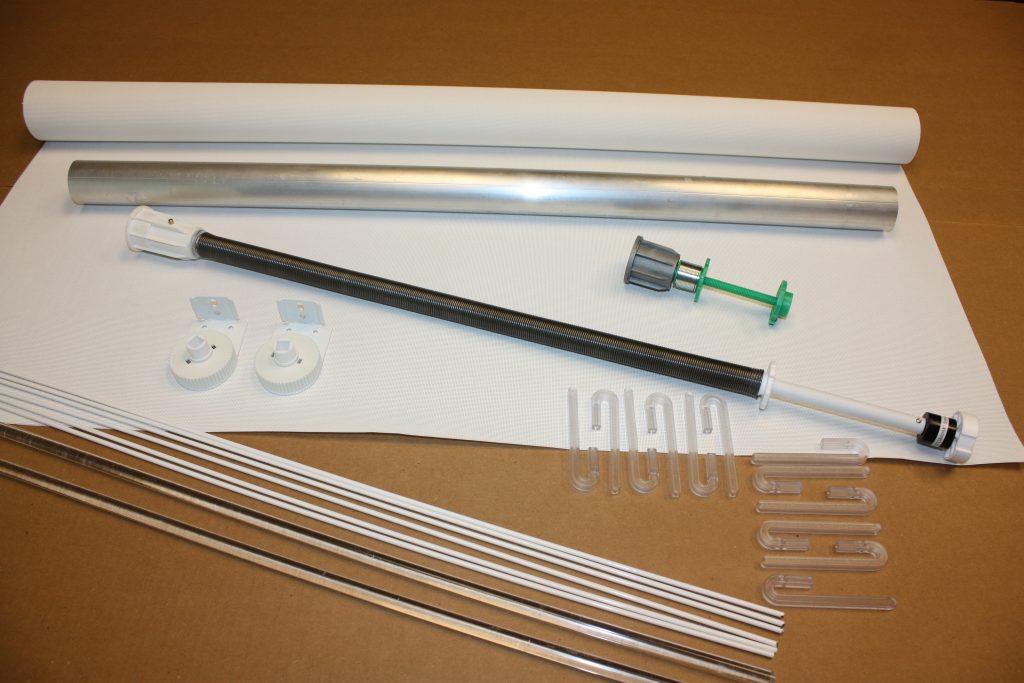

Some of the clutch systems include the Roman Blind System (RBS) from Forest Group, R-TEc EZ Rig Soft Shade System and Soft Shade Traversing Clutch System from Rowley, and RollEase Board Mounted Workroom System and the SS38 Roman Shade System by Rollease Acmeda. Each of these systems work with a clutch on one side of the tube or rod that has a chain connected to the clutch. Clutch systems have lift cords on the back of the shade with the same number of cord clips or drums where the cord attaches to the rod or aluminum tube, depending on the type of operating system selected.

Döfix Auto-descend would be included in the clutch system family, but it has a semiautomatic feature to its clutch. When the operating chain is securely attached, a simple tug to the chain will cause the shade to lower or “auto-descend.”

ProLift Profession Lift System by Safe-T-Shade has a clear Fashion Wand that houses the beaded loop operating cord. The distinguishing feature of this system is the Fashion Wand, which creates a corded operating system where the cord is enclosed, making it inaccessible. There is a Fashion Wand cradle that attaches to the mount board so the wand can be hidden behind the top of the shade.

Spring-Loaded Systems

Spring-loaded systems work similarly to traditional roller shades. There is a 1.5-inch tube that attaches to the mount board. The tube houses the spring and stop that will allow the shade to have an upper stop position. Without this being set, the shade will not raise and be stuck in the down position. While these do not have operating cords, they do have lift cords on the back of the shade.

Spring-loaded systems include the Easy Spring Plus by Rollease Acmeda and MYL Shield Spring Shade Operating System Kit by Merrill Y. Landis.

Motorized Systems

Many of the operating systems we have discussed previously can be motorized. For example, Forest Group’s RBS can now be motorized with your choice of a standard or lithium-ion motor.

Pro Design LLC houses the motor in a 1.5-inch tube, similar to one of the spring-loaded systems. This system can be remote, wall or integrated into a hub system. There is also the option to attach a wand to the tube. The bottom of the wand is shaped like a teardrop, with buttons to raise and lower the shade. Rowley and Merrill Y. Landis sell wand-controlled motorized systems by Rollease Acmeda.

The only completely cordless operating and lift system is the Wide Band Lift System from Safe-T-Shade. There are several outstanding features about this shade. Besides being completely cordless, there is a choice of 10 percent openness or a complete blackout lift sheet to replace the cords. This gives the back of the shade a clean, smooth look from the street. Battens are used along with j-guides and can be placed more than eight inches apart if you want to change the stack size because you are pleating to pattern. This system is spring-loaded, and you can choose between two different spring sizes depending on the weight of the shade.

Photo courtesy of Safe-T-Shade

Safe-T-Shade’s ProLift Professional Lift System can be motorized, with the option of selecting two different motor sizes. The Light Lift LL-13 will lift up to 13 pounds. The Medium Lift ML-23 will lift up to 23 pounds. The Heavy Lift HL-70, which will lift up to 70 pounds, is coming soon.

While I am sure that the standards and operating systems I have discussed are not all-inclusive, it is my hope that I have given you enough information to sell, source and fabricate draperies and shades according to the new safety standards. The safety of our families is the impetus to find innovative solutions for safe operating systems for blinds, shades and draperies. New products and the education needed to implement the new standards help the industry to continue to develop best practices.